cb-625 calibration tool

Where are the cb-625's?

Once more Iím getting a lot of emails asking where the cb-625ís have gone because there

are none in the shops and our website shows no-stock.

We have a new production delay, once again due to the electronic calibration tool.

Only 550 of the latest batch passed the electronic test at the factory. I am hoping they have sent me the 550 but this

has not yet been confirmed.

I suspect that the electronic calibration problem has always been there, but the new

calibration man is being a lot more picky. I heartily approve.

I have sent new software for the calbration tool which should fix the problem.

Apologies for the delay, hopefully it wonít be too long. I will post any news here as soon as I have it.

Robin Hewitt

Combro Ltd

Update 5/7/10

It seems the new software did not fix the problem so I spent most of last week shut away with

a digital storage oscilloscope fine tuning the calibration software and adding extra tests to

diagnose what is going wrong. This has put me very behind with answering emails, sorry if you

have had to wait.

Fixing the fault is extra tricky because I do not have a cb-625 that fails the test so I am rather groping

in the dark. I have asked for examples of the failing units to be sent. I do not think this has been done.

If I get a failing cb-625 I will have the answer within the hour. If I get the new test results I will be

close to a fix. Short of leaping on the next 'plane to China I am a bit stuck. More when I have it.

Update 26/7/10

Today we received 200 tested cb-625's, another 50 with the fault (box #6) and 50 interface cables.

Box #6 seems to be passing the test shooting, maybe the boxes got renumbered? It's a bit of

a lucky dip. It will be a few days before I send any out. There has been a component change in some

transistors, the new part seems to have the same characteristic as the original part but I need to be sure,

("same characteristic" being electronics speak for "behaves the same way when you jiggle the pins").

Confidence is that feeling you get just before you understand the problem, so no promises until

I have tested at least a hundred and found the elusive box #6. Nothing goes out the door until I know they

won't be coming back. There may also be extra delay when I find the mystery box

because fixing the calibration problem and restarting production has to be a priority.

Update 3/8/10

Three steps forward, one giant leap backwards. The calibration tool is now fixed, the 250 pcs I received are nearly done,

the transistor change proved a Godsend because it suddenly became linear and I was able to simplify the

calibration process enormously with some new software. I was just starting to feel all warm and cosy when Arizona

Microchip decided to put the cb-625 processor chip on allocation with a 26 week lead time.

Allocation and a 26 week leadtime is normal practice for chip suppliers the moment they realise that demand for a

part exceeds supply and customers are about to start panic buying. It's a sort of knee jerk response.

Usually they increase capacity and get over it in a lot less than 26 weeks, but things may be somewhat complicated

because the chip has been cloned and is a "mature" part. (Mature meaning getting a bit long in the tooth, not recommended

for new designs because they are thinking about discontinuing it).

Obviously we tried the clone and found that it works fine and dandy except for the standby

current consumption. Basically, it will eat the battery. Blank samples of the clone and a new programmer have been

ordered because this is probably fixable.

Right now I am looking for stock of the Arizona part, I have to find suppliers with stock who are unaware of a problem

which means they can double the price. I have 38 in hand and another 746 have just cleared Customs at Stanstead.

They have 70 at the factory and are looking for more.

For the Nerds (updates at bottom)

The calibration tool is a bed of nails tester used to calibrate the cb-625 circuit board once the optics

have been fitted, but before it gets screwed in to it's plastic case. The cb-625 has 14 gold

plated contact pads which connect to 14 sprung contact pins on the tester.

So what is the problem? Part of the test is faking shots through the cb-625 to see if it gets the speed

right, which means firing the optics.

It can't physically break the light beam so the circuit switches off the transistors driving the

LED's. Turning off an LED produces much the same result as breaking the light beam with a pellet.

The calibration tool mimics pellets at 100 and 500 ft/s, displaying the result from the

cb-625 serial output.

It seems the pulses were not quite long enough, the optic volts did not necessarily rise high enough

to fool the cb-625 in to thinking it had been shot through. Longer pulses were required to allow

for the transistor switching times. The photodiode side of the circuit is balanced on a knife edge and

responds a lot faster than the LED side which ramps.

The 6 microsecond pulse did not switch it reliably, the cb-625 under test sometimes failed to report and

the calibration tool threw a, "No response" error message.

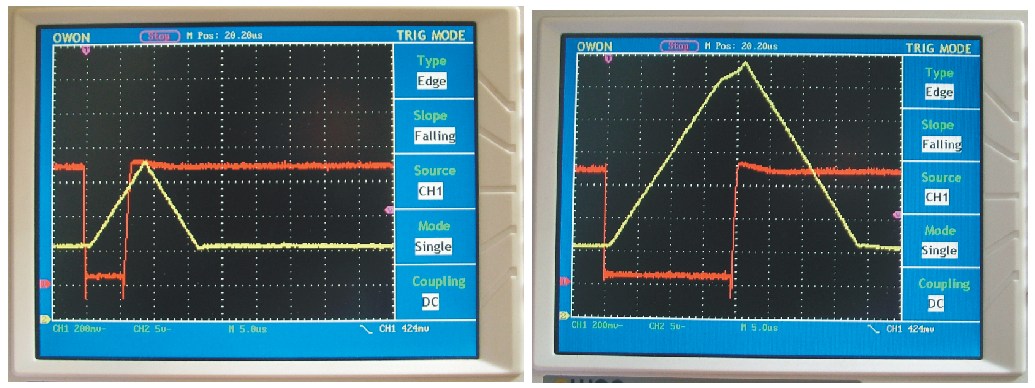

The new software patch increases the delay to 19uS which gets a much bigger response and

should fix the problem. Here is a before and after trace, the red line is the switching pulse,

the yellow line shows the output ramping up as the LED fades. The before trace only just failed to

switch so we now have lots of headroom.

Normal electronic calibration acceptance limits are plus minus 2 clocks at 4MHz, approx 0.6ft/s

at 500ft/s. Calibration is by adjusting the baseline voltage, effectively how far the pellet has to enter

the light beam before it switches.

Nerd update 5/7/10 When you interrupt a cb-625 optic the output volts ramp at about

6uS/volt, (we are looking for a 0.5v to 1v swing). The photodiode reponds in nanoseconds but pushes

against the capacitance of a transistor base.

6uS is about the time it takes a full power, 800 ft/s, 0.177 pellet to travel the 1.5mm beam width

so it is not exactly restrictive unless the pellet is less than 3mm long, worst case, which is unlikely. The ramp

should correspond to the occlusion of the beam and effectively cancel out of the equasion until

you reach supersonic and a pellet length becomes more important.

The calibration tool does not have capacitance issues when it kills the LED to simulate a shot, effectively

instantaneous.

If the test fault is real, I am far from convinced, there is the possibility that they have fitted a very capacitive transistor.

I have suggested they try replacing the transistors with a superior part, (ie: in spec), and repeat the test.

In reality, I think the fault is already fixed but they need encouragement to start testing again. To that end I have

added extra facilities to the calibration software, asked them to insert a failing cb-625 in the calibrator,

force the optics on, run the sensor volts test, measure the volts by voltmeter to confirm they are being measured

correctly (the calibrator buffers the sensor output through ultra low capacitance unity gain op-amps), physically

break the light beams while repeating the test and then tell me what they find. Hopefully this will do the trick.

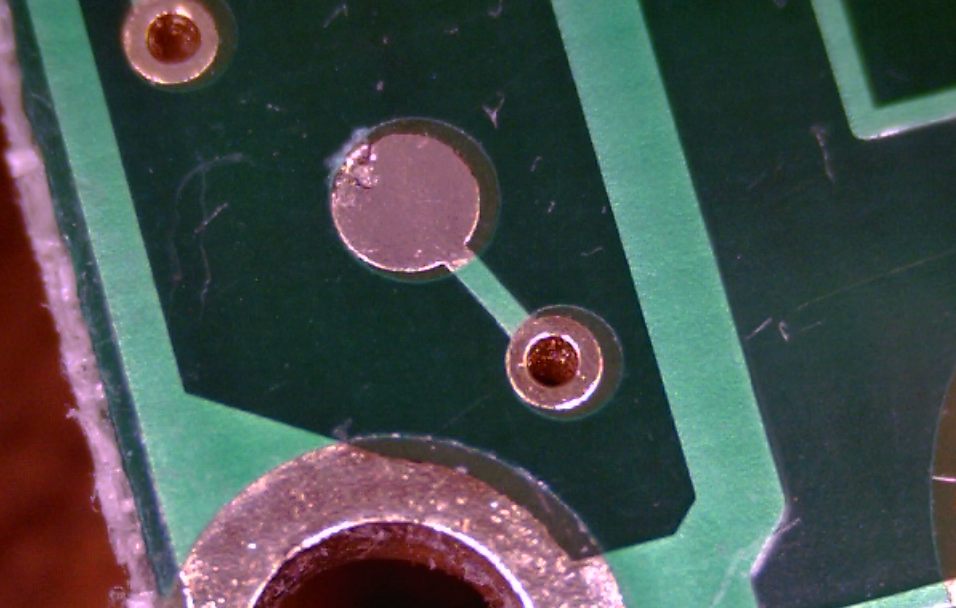

Nerd update 26/7/10 Now I have failing boards to look at, my new guess at the cause of the calibration tool failure.

There may be a bent pin on the bed of nails. Pic shows a contact pad on a cb-625 with marks on the resist

that could be misses. Misses on this pad would fail the pretend shot test